Messer/Mayer Mill

History of a Richfield Treasure

The Messer Family

Johann Messer and his family emigrated to the Richfield area from

Hesse Darmstadt, Germany in 1846. The family consisted of Johann and

his wife Charlotte (Mayer) and their four children. They purchased 120

acres for $150 and farmed the land. In 1856, recognizing the

opportunity of a value  added business, Johann constructed a sawmill on his property using the water from Coney Creek as the power source.

added business, Johann constructed a sawmill on his property using the water from Coney Creek as the power source.

Sawmills were in demand in the area. The primary agricultural product of southeastern Wisconsin was grain, but the wooded landscape required clearing before crops could be planted. The resulting surplus of hardwood logs was ideal for building homes and farm buildings, but sawmills were necessary to convert the logs into building lumber. Due to the poor roads, hauling logs was difficult so local mills were a necessity. As a result, practically every location that had flowing water was utilized for a water powered mill.

Grain farming was so successful in Wisconsin that the state became

one of the leading wheat producers. It has been said that the Union

Army in the Civil War was fed with bread from Wisconsin wheat. As

Johann Messer came to the end of his working career in 1869, he divided

his holdings among his children, and the 27-acre parcel that included

the Sawmill went to his son Andrew. Recognizing the potential offered

by the cash crop, wheat, Andrew  began the construction of a grist mill (grain mill) next to the Sawmill

in 1871. The grist Mill was barely completed when Andrew was killed in

a horse accident in 1874. Unable to operate the two businesses and also

raise a family of three children, his widow Louisa sold the business to

her husband's uncle Johann George Mayer in 1876.

began the construction of a grist mill (grain mill) next to the Sawmill

in 1871. The grist Mill was barely completed when Andrew was killed in

a horse accident in 1874. Unable to operate the two businesses and also

raise a family of three children, his widow Louisa sold the business to

her husband's uncle Johann George Mayer in 1876.

The Mayer Family

The eldest son of Johann Mayer, Karl Wilhelm (known as C.W.) purchased the Mills and property from his father in

1885. He and his wife Mary Anna raised a family of seven children on

the property, operating the Mills and running a small farm for family

needs until his death in 1917. C.W. and Mary Anna’s eldest son, George,

and his brother Charles (Milton) ran the Mills until 1930. At that

time, Charles sold his interest to George. George and his wife Martha

raised two children (Vernon and Carol) on the property.

(known as C.W.) purchased the Mills and property from his father in

1885. He and his wife Mary Anna raised a family of seven children on

the property, operating the Mills and running a small farm for family

needs until his death in 1917. C.W. and Mary Anna’s eldest son, George,

and his brother Charles (Milton) ran the Mills until 1930. At that

time, Charles sold his interest to George. George and his wife Martha

raised two children (Vernon and Carol) on the property.

The End of an Era

The Sawmill ceased operation in 1930 due to the competition from

inexpensive lumber available in retail stores. The building stood

unused until it collapsed in 1951. The grist Mill, however, continued

in operation grinding grain until the 1930s. At that time, as the

market shifted to cheaper and more easily available flour in

stores, the need for local grinding ceased. George continued grinding

cattle feed at the Mill and selling feed and supplements until the 1950s. But the days of a local business to

provide these services were ending. Farmers were increasingly able to

grind their feed using their own equipment, and improved transportation

meant that agricultural necessities like those George Mayer provided

were widely available and at lower costs.

supplements until the 1950s. But the days of a local business to

provide these services were ending. Farmers were increasingly able to

grind their feed using their own equipment, and improved transportation

meant that agricultural necessities like those George Mayer provided

were widely available and at lower costs.

At the end, George’s customers dwindled to three, and he closed the doors on the old Mill in 1954. George Mayer passed away in 1973. At that time, the property had been in the Mayer family for almost 100 years. The property was sold out of the Mayer family and forgotten for decades.

Just In Time

A few Town of Richfield residents, recognizing the Mill’s

significance, approached the Town Chairman, Ralph Schulteis,

who had fished in the mill pond in his youth, suggesting it be

purchased. The property was purchased by the Town in 1998 from

development impact funds and leased under a long-term lease to the

Richfield Historical Society.

Ties to a Wisconsin Giant

The equipment in the grist Mill has significant importance to the

history of southeastern Wisconsin. Virtually all of the equipment was

manufactured by the Edward P. Allis Company and its successor company,

Allis Chalmers. Edward P. Allis was, like many of the early

settlers of Wisconsin, a native of New York. He came to Wisconsin in

1846 and immediately became involved in the business of manufacturing.

First he engaged in leather and tanning, but in 1861, he purchased the

Reliance Works in Milwaukee, the business that would soon take on his

name. Allis built the company into one of the premier manufacturers of

milling machinery in the world. The firm had other divisions, but

milling was the largest for years.

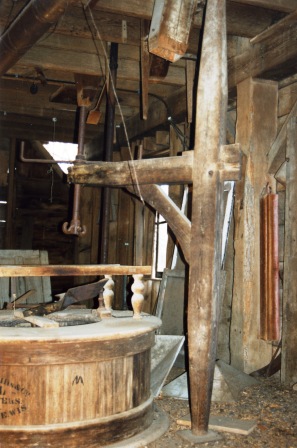

Complicated and Complex

The grist Mill that Andrew Messer planned to build in 1871 was a

complicated operation that required machinery to move grain and flour

between different levels and operations, grind grain into flour, sift the flour and,

finally, bag the flour. The proper design of such a complex series of

operations was essential for the Mill to operate efficiently. The Mill

required design and specialized machinery that was not available to the

average person. The solution was to hire a specialized mill design firm

that could also supply the equipment.

levels and operations, grind grain into flour, sift the flour and,

finally, bag the flour. The proper design of such a complex series of

operations was essential for the Mill to operate efficiently. The Mill

required design and specialized machinery that was not available to the

average person. The solution was to hire a specialized mill design firm

that could also supply the equipment.

We believe Messer retained the Edward P. Allis Company and that Allis supplied a general designer who also supervised the construction, a specialist called a millwright. The millwright would lay out the plan for the Mill and the equipment and supervise the construction and machinery installation. The lumber for the building came from the Messer Sawmill, but everything else was supplied by Allis. Visitors to the Mill can see the equipment that was initially installed including the stone grinding wheels (two sets), the sifting machinery (called bolting machines), elevators to move the grain and flour between floors and operations, storage bins and the bagging equipment. Later additions include four stands of roller mills (also supplied by Allis in the early 1890s), the related sifting machinery for the roller mills, and an electric burr mill to grind animal feed in 1927.

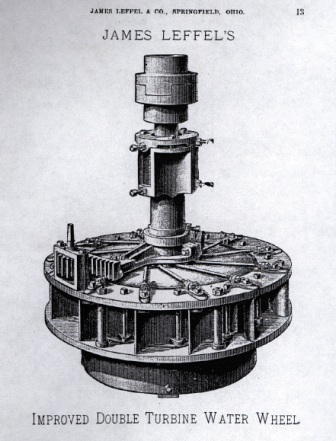

Powering the Operation

The Mill was initially powered by water which ran through a turbine

designed by the Leffel Company of Ohio. The turbine was purchased in

1872  from

Leffel through E. P. Allis as part of the Mill design. The turbine

supplied the equivalent of about 25 horsepower. Water turbines were

developed in the 1860s and were more efficient users of water than the

previous overshot water wheels. Coney Creek, the water supply for the

Mill, had limited flow, and it is questionable whether the grist Mill

could have been operated with a water wheel instead of the more

efficient turbine. In the early 1900s the Mayers obtained different

internal combustion engines to supply power when the water supply was

limited.

from

Leffel through E. P. Allis as part of the Mill design. The turbine

supplied the equivalent of about 25 horsepower. Water turbines were

developed in the 1860s and were more efficient users of water than the

previous overshot water wheels. Coney Creek, the water supply for the

Mill, had limited flow, and it is questionable whether the grist Mill

could have been operated with a water wheel instead of the more

efficient turbine. In the early 1900s the Mayers obtained different

internal combustion engines to supply power when the water supply was

limited.

The original engine is missing, but the Richfield Historical Society (RHS) has obtained and restored a 1913 Superior engine that we believe is very similar to what the Mayers used. This will be used to power the Mill when we get it operational. The third source of power used for the Mill was electricity. Electricity came to the area in 1927, and the Mill was converted to operate with this source of power.

Community Hub

The historical significance of this small business cannot be

overstated. It presented a focal point for the social life of the

agricultural community that it served. Farmers came to the Mill to get

their grain ground but visited with their neighbors while they were

waiting. Farm life was arduous and essentially lonely due to the long

hours and distance between neighbors. A visit to the Mill presented an

opportunity to take a break and enjoy some conversation.

A Treasure Saved

The fact that George Mayer chose to leave the Mill and its machinery intact, means that we now

have a wonderful opportunity to view all of the machinery as it was

when the Mill was running. Three generations of milling technology

dating from ancient stone grinding to the modern roller mill, three

generations of power from the ancient use of water to the modern

electricity are all represented in this historic building. The

Messer/Mayer Mill just happened to be built and operated when all these

changes in technology were occurring. The Town of Richfield had the foresight to save this treasure

in 1998. The result of all these events is that we can today

witness a rare opportunity to see, not a simulation, but the real means

by which some of our early Wisconsin pioneers operated and prospered.

three

generations of power from the ancient use of water to the modern

electricity are all represented in this historic building. The

Messer/Mayer Mill just happened to be built and operated when all these

changes in technology were occurring. The Town of Richfield had the foresight to save this treasure

in 1998. The result of all these events is that we can today

witness a rare opportunity to see, not a simulation, but the real means

by which some of our early Wisconsin pioneers operated and prospered.